Wire rope and cable can come in a huge variety of forms, but coiled cables specifically provide the benefits of easy storage and tidiness. Unlike other wire ropes, coiled cables do not require a spool for storage. Because it has been coiled, the cable will automatically retract into its spring-like shape when it is not in use, making it incredibly easy to handle. Read More…

As leading innovative wire rope manufacturers, Bergen Cable Technology has been providing engineering assistance for well over half a century, helping customers develop cost effective, durable solutions.

JSC, as one of the most diversified wire rope manufacturers, utilizes over 200 production machines to produce top rated wire products in ferrous and nonferrous materials. Industries that JSC serves include electronics, geophysical and communications.

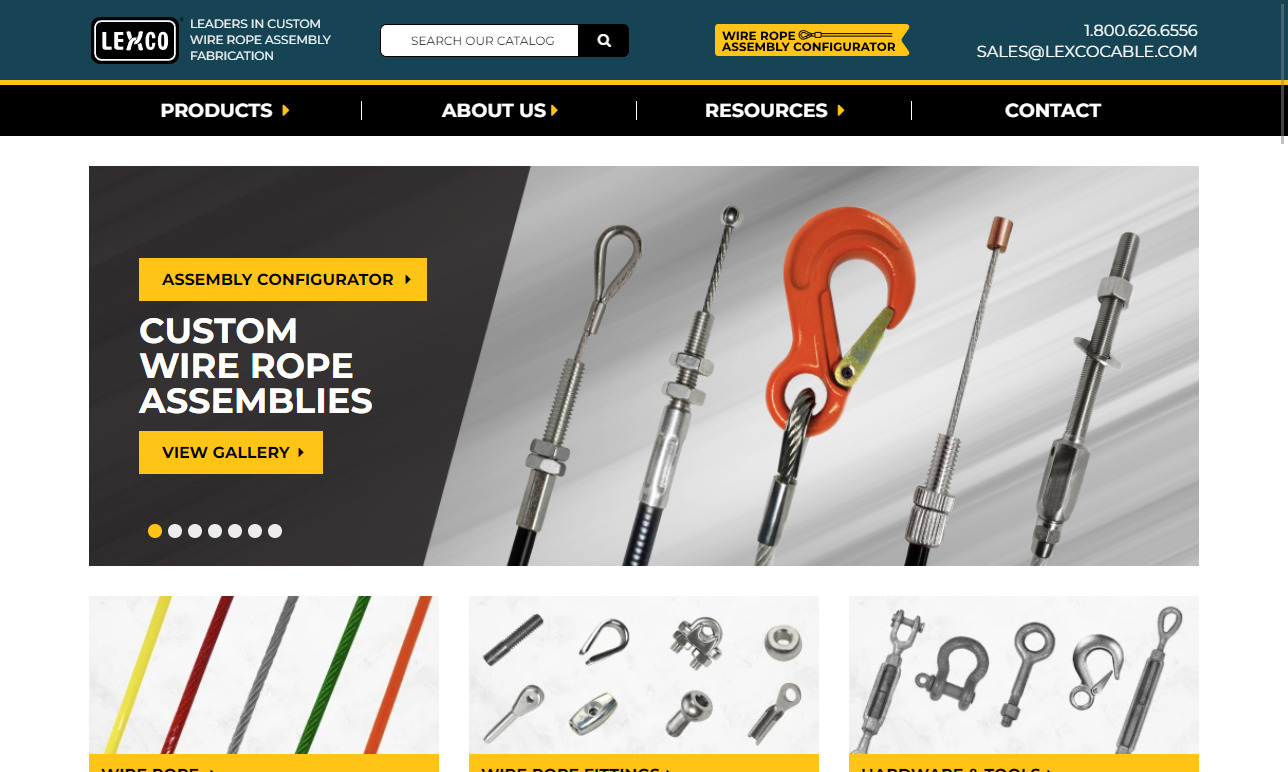

Lexco is an ISO:9001 manufacturer of wire rope, cable, and bungee cord assemblies; and push-pull controls. Our in-house capabilities range from swaging and extrusions to die-casting, proof-loading, and CNC machining. Lexco Cable is proud to serve a diverse set of markets including military, aerospace, OEM, MRO, marine, architectural, and more. Contact us today.

For over 30 years, companies across various markets have relied on Motion Control Technologies to provide high-quality mechanical cable solutions. Our line of products includes commercial cable lanyards, galvanized wire rope cable lanyards, swaged fittings, and more. We strive to build long-lasting relationships with our customers, regardless of your industry. Contact us today and tell us how we...

Aero Assemblies, Incorporated strives to make every effort, as dedicated wire rope manufacturers, to maximize product value throughout the manufacturing process.

More Coiled Cable Manufacturers

Like other wire ropes, cables are made up of strands, and each strand is made up of smaller metal wires. Each cable can be customized to fit the needs of a given application by using a different number of wires, a different number of strands, and different materials.

Strands are usually made from wire bundles with seven, thirteen, and nineteen wires because a circular configuration can be achieved easily with these bundle sizes. For example, a strand of seven wires is made from a single central wire surrounded by six wires.

In the same way, cables are also commonly made with seven, thirteen, and nineteen strands. Other configurations are possible, and many cables will use other materials within the cable, such as a fiber core instead of a central wire strand.

The number of wires and strands has a significant impact on the strength and durability of the cable. Typically, a larger number of wires will help increase the cable's resistance to fatigue, allowing the cable to hold heavier loads for prolonged periods of time. A larger number of wires also improves the flexibility of the cable.

Additionally, larger wire diameter increases the cable's resistance to abrasion and crushing, making it more durable and less likely to break due to wear. However, thicker wires will also reduce the flexibility of the cable.

Therefore, it is incredibly important to consider which aspects of the cable are most important for your application.

In order for a cable to be coiled, it must be fairly flexible, so most coiled cables are constructed from thinner wires. This means that coiled cables are often more susceptible to wear and tear from heavy use or exposure to larger forces. For this reason, coiled cables are more frequently utilized in commercial and personal applications as opposed to heavy duty industrial applications.

Security applications are possibly the most common uses for coiled cables. Wire ropes can be equipped with a variety of end fittings, including locking mechanisms. Bicycle locks are a common example of coiled cable use. The cable can be wrapped around the bicycle and a large permanent structure, such as a bike rack, with the ends of the cable locked together. They also coil up into a relatively small size, which makes them easy to transport as you move from place to place.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services