Push-pull control cables are employed to transfer motion. Push-pull cables offer an effective and affordable solution to control issues brought on by stricter laws against noise and the need to enhance driver comfort while improving machine accessibility for maintenance. Read More…

As leading innovative wire rope manufacturers, Bergen Cable Technology has been providing engineering assistance for well over half a century, helping customers develop cost effective, durable solutions.

JSC, as one of the most diversified wire rope manufacturers, utilizes over 200 production machines to produce top rated wire products in ferrous and nonferrous materials. Industries that JSC serves include electronics, geophysical and communications.

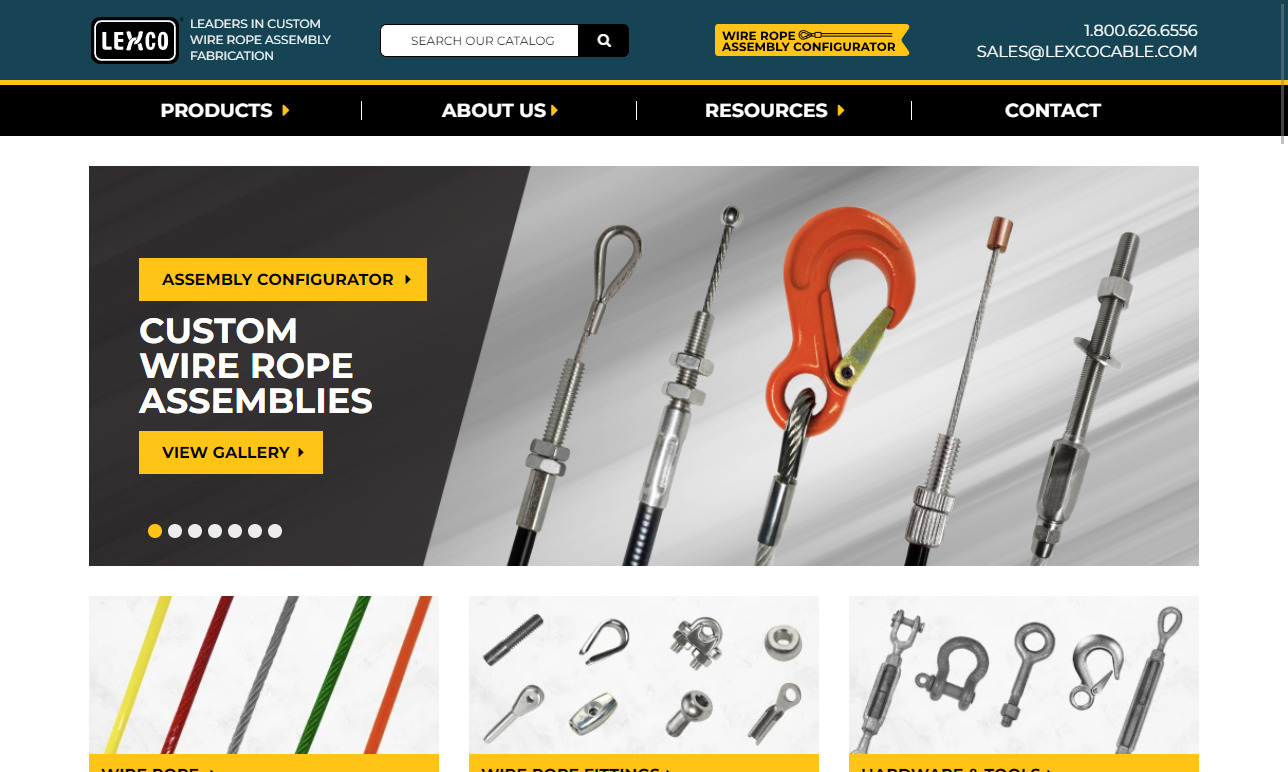

Lexco is an ISO:9001 manufacturer of wire rope, cable, and bungee cord assemblies; and push-pull controls. Our in-house capabilities range from swaging and extrusions to die-casting, proof-loading, and CNC machining. Lexco Cable is proud to serve a diverse set of markets including military, aerospace, OEM, MRO, marine, architectural, and more. Contact us today.

For over 30 years, companies across various markets have relied on Motion Control Technologies to provide high-quality mechanical cable solutions. Our line of products includes commercial cable lanyards, galvanized wire rope cable lanyards, swaged fittings, and more. We strive to build long-lasting relationships with our customers, regardless of your industry. Contact us today and tell us how we...

Aero Assemblies, Incorporated strives to make every effort, as dedicated wire rope manufacturers, to maximize product value throughout the manufacturing process.

More Push Pull Cable Manufacturers

Push-pull assemblies are utilized when force transmission is necessary for both directions of assembly travel. A nice illustration of this is the choke on a lawn mower engine. Customized push-pull assemblies provide multidirectional control for precise and reliable mechanical motion control. Push-pull assemblies are flexible and adjustable to fit into various applications.

They are simple to connect to various points on machinery, intricate control systems, or automated machines, thanks to their strong wire fittings. In addition, push-pull assemblies' adaptability provides a reliable method of transmitting motion between fixed points or ones whose relative positions are continually changing.

Examining the workload for the push mode is the first step in the design process for push-pull assemblies. This inner wire may encounter resistance as it moves, resulting in distortion and buckling, especially if it protrudes from the conduit. Therefore, the inner wire's diameter can be raised to accommodate the workload to compensate for this occurrence.

When developing push-pull assemblies, engineers must consider various elements, such as the inner wire in the push mode. Although a push-pull assembly's basic function may be straightforward, correct calculations are required to guarantee their successful operation. Push-pull cable controls have countless applications in various industries, from extremely complex aerospace components to backyard gardening tools.

They are made to regulate operations, modify mechanisms, and activate different parts. Push-pull cable controls would become obsolete with the arrival of the computer era. However, push-pull control cables have proven crucial for programming automated machinery. Furthermore, push-pull controls are appropriate for various computer run functions due to its adaptability, adaptability, accuracy, and perfect performance.

How Push-Pull Assemblies Are Made

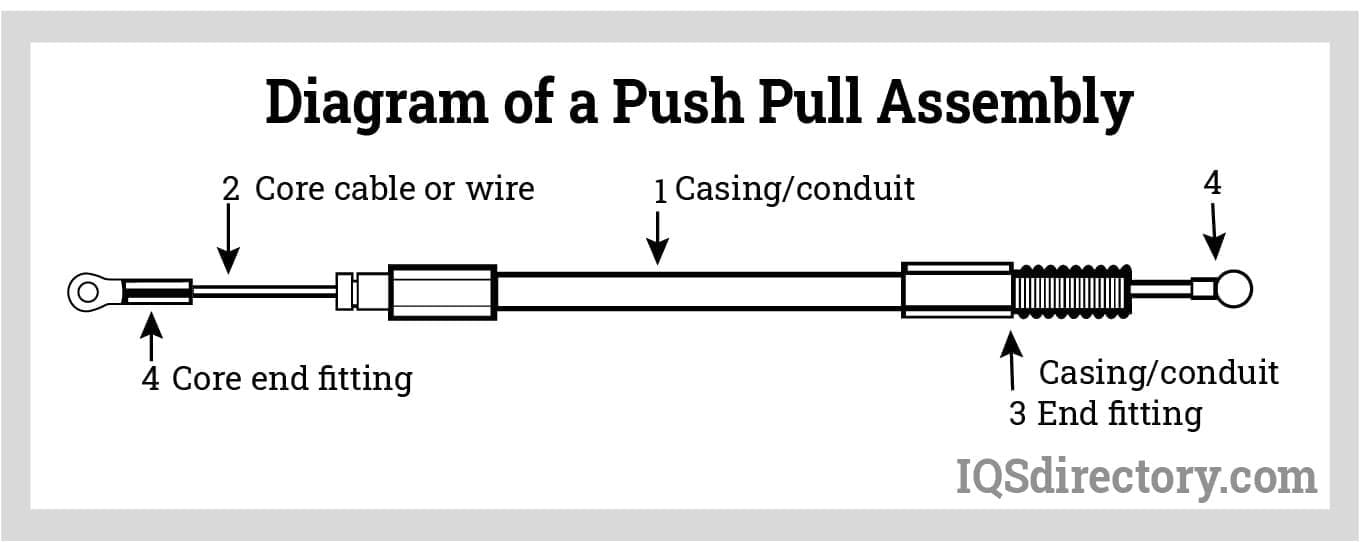

Machine design depends heavily on the creation of push-pull assemblies. A well-designed push-pull assembly ensures powered functions' proper operation and extended lifespan. Push-pull assemblies, also known as control cable assemblies, are responsible for various operations, including braking, choking, rotation, drive latches, hood releases, and throttles. Each component that makes up a push-pull assembly is carefully considered throughout the design stage because flaws in the Assembly can significantly affect its performance. Even though push-pull assemblies come in various forms, all varieties have a few common components.

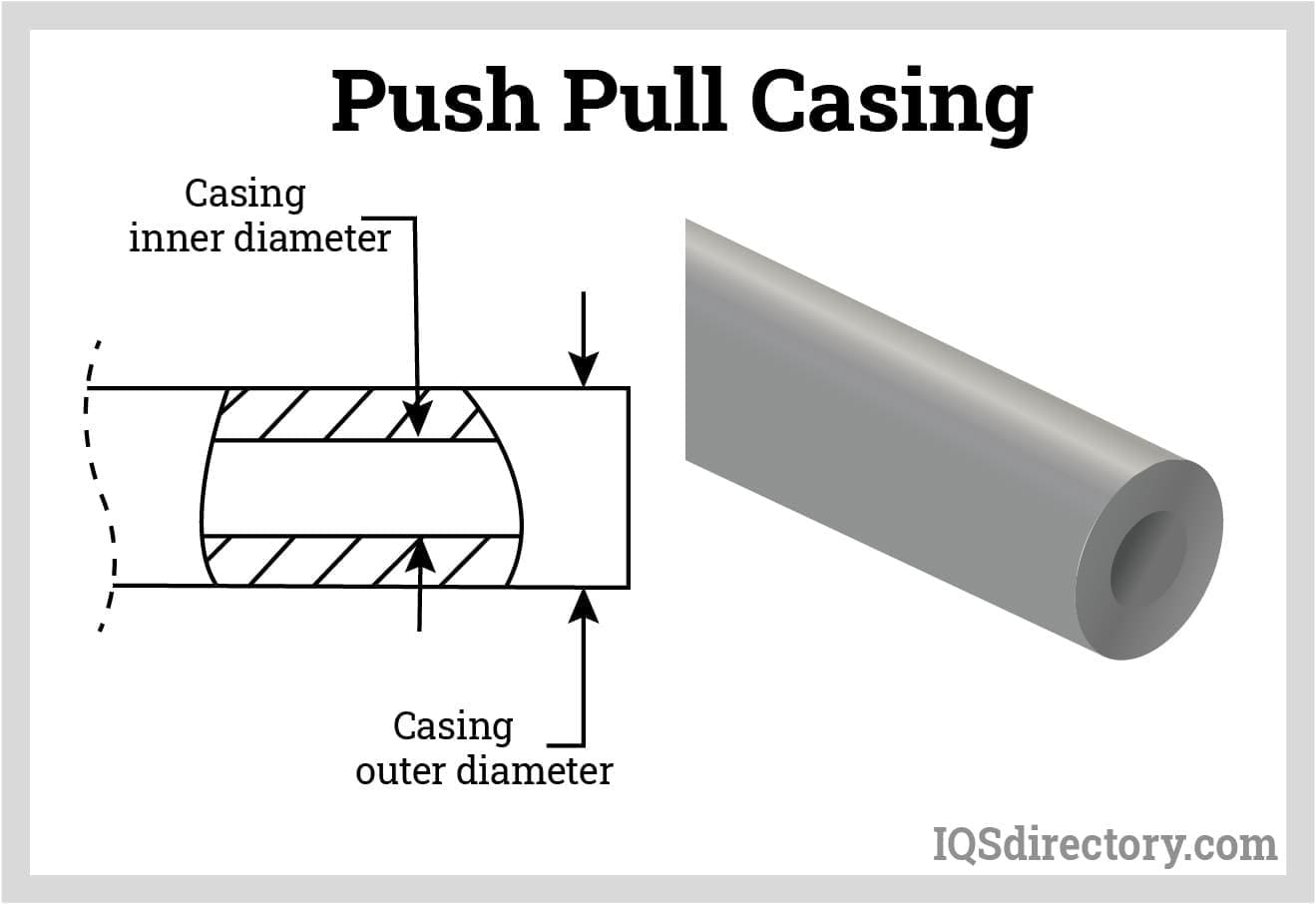

Assembly Casing

The conduit, another name for the shell of a push-pull assembly, acts as a guide for the inner core. The casing is made from various materials, including spiral-wrapped wire, nylon, plastic tubing, and galvanized steel. The casing's flexibility enables the control system to be bent to accommodate routing requirements. In addition, various fittings can be fitted to the casing to improve the ease of use. Casings have an outside diameter that is sturdy and durable enough to protect the mechanism and an inner diameter where the cables are installed.

Bulkhead Terminal

The bulkhead terminal is swaged to the casing to mount the push-pull control into a panel, bulkhead, or other solid portion of a mechanism. They are typically made of brass, steel, or stainless steel.

Uses Of Push-Pull Cable Controls

Aerospace Uses

Modern aircraft need reliable components to meet the demands of safe control and outstanding performance. Push-pull cable controls provide the option of remotely activating aircraft systems. Push-pull cable controls are a great option for airplanes because they can withstand the tremendous tension and compression forces experienced during flight. In addition, they are constructed in short lengths for aircraft controls to avoid vibration and bending under compression.

Marine Uses

Boats employ push-pull controls frequently. They mechanically link the clutch and throttle to the control head. They are the perfect answer for boats with one or two control stations and a cable length under 50 feet (15.2 m). When using a single lever control, the clutch is engaged by moving the lever forward. Speed increases as the lever is pulled farther forward. By pulling back on the lever, the actions are reversed.

Usage in Lawn Mowers

Lawnmowers' push-pull control cables are used as throttle cables to regulate the mower's speed. The push-pull control cable is directly attached to the intake valve of the carburetor in contemporary lawnmowers. A throttle cable can withstand a maximum push force of 10 lbs (4.5 kg) and a maximum draw load of 25 lbs (11.3 kg).

Usage in Trucks

Push-pull control cable assemblies are used in heavy machinery like trucks to engage a variety of functions and processes. For example, there are cables for controlling the front winch, the dump body, the shift, the transmission engaging, the defrost, the engine stopping, and the throttle, to name a few. Operating heavy-duty vehicles is made simpler and more effective with the help of these various push-pull control cables.

Other Push-Pull Control Cable Uses

The few push-pull applications discussed here represent just a small portion of the numerous possibilities for push-pull control cables. They are used in various applications, including construction machines, programmable software, and industrial machinery. In addition, they are frequently utilized because their primary roles involve precisely triggering and regulating processes.

Advantages of Push-Pull Cables

- Flexible applications

- Significantly fewer wear points than rod systems

- Unaffected by inter component motion, such as cables being sprung, power packages rolling, temperature changes, etc.

- Low transmission of noise

- Shortened line assembly period

- Simple cab sealing

Choosing the Correct Push Pull Cable Supplier

To make sure you have the most beneficial outcome when purchasing Push Pull Cables from a Push Pull Cable Supplier, it is important to compare at least 4 or 5 Companies using our list of Push Pull Cable suppliers. Each Push Pull Cable Company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Push Pull Cable business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Push Pull Cable businesses with the same form.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services