There are different ways of creating wire ropes, and each produces a rope that offers unique stress and rotational qualities suited to specific tasks. For most tasks, the two primary types of rope in use are stranded and spiral wire ropes.

Stranded wire ropes—steel strands wound in one or more layers around a core made of synthetic material, a wire strand, or a wire rope—secure loads as wire rope slings or running ropes because, in addition to being stressed by tensile forces, they take stress by being bent over the items that they are securing.

The three types of spiral wire rope, steel strands wound in opposing helical layers to make them nearly non-rotating, offer their own positives and negatives. Open spiral wire rope, made only from round wires, is suited to lighter applications. The half- and full-locked variants have a round wire core surrounded by profile strands that protect the rope and keep it lubricated. Given these qualities, spiral ropes are generally used as stationary ropes and stay ropes as they are good with both static and fluctuating tensile stresses. Full-locked ropes also serve as track ropes for cable cars, ski-lifts, cranes, and similar machines as they experience an increase in their free-bending radius when the tensile force increases, decreasing the bending stresses on the rope. As the roller force increases, however, that tensile force, along with the free-bending radius of the rope, decreases.

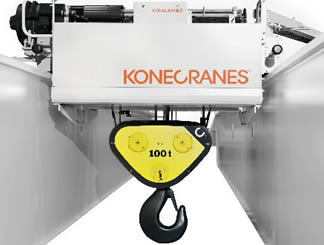

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services