Wire rope is a highly complex mechanical tool with many working parts to support and move a load or object. Wire rope with swivels, shackles, or hooks is attached to a crane or hoist in the lifting and rigging industries so that it can be used to move cargo gently. Additionally, it can lift and lower suspension bridges, support towers, and elevators. This article will explain the parts of a wire rope, how it’s made, and the various kinds of wire rope. Read More…

As leading innovative wire rope manufacturers, Bergen Cable Technology has been providing engineering assistance for well over half a century, helping customers develop cost effective, durable solutions.

JSC, as one of the most diversified wire rope manufacturers, utilizes over 200 production machines to produce top rated wire products in ferrous and nonferrous materials. Industries that JSC serves include electronics, geophysical and communications.

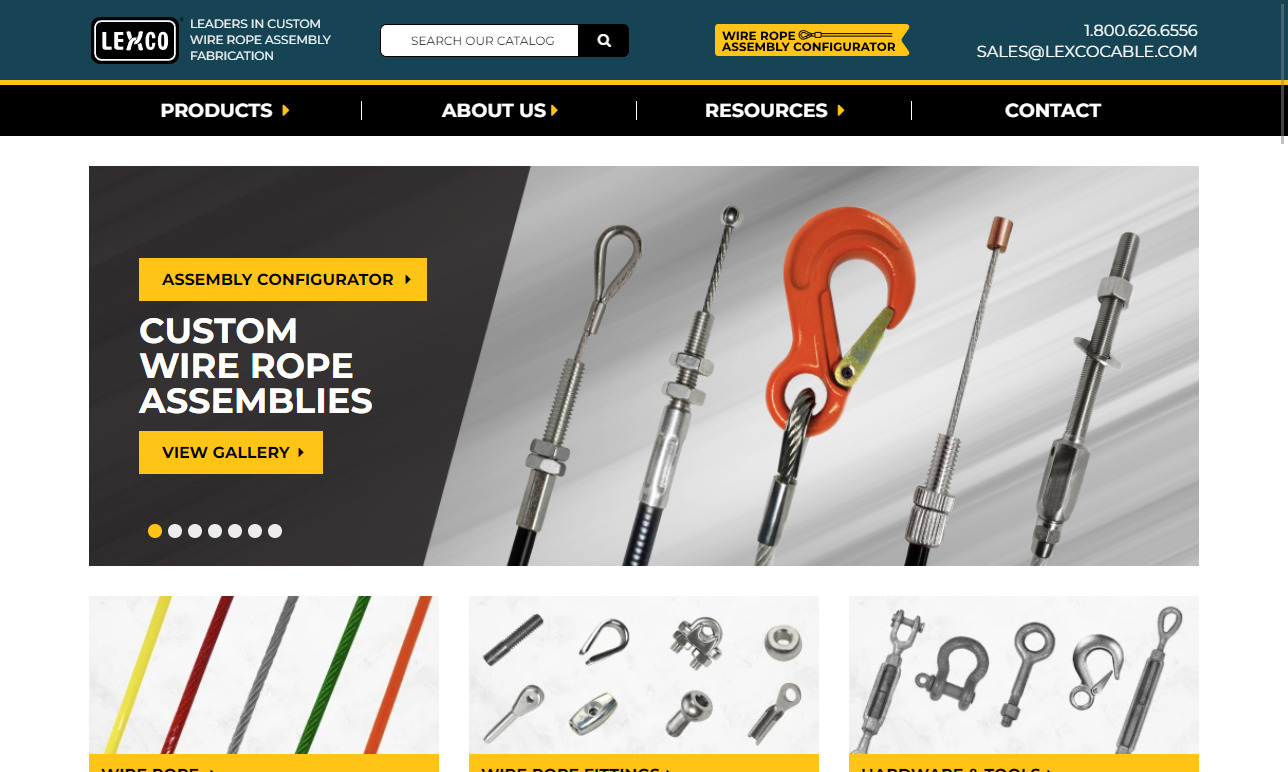

Lexco is an ISO:9001 manufacturer of wire rope, cable, and bungee cord assemblies; and push-pull controls. Our in-house capabilities range from swaging and extrusions to die-casting, proof-loading, and CNC machining. Lexco Cable is proud to serve a diverse set of markets including military, aerospace, OEM, MRO, marine, architectural, and more. Contact us today.

For over 30 years, companies across various markets have relied on Motion Control Technologies to provide high-quality mechanical cable solutions. Our line of products includes commercial cable lanyards, galvanized wire rope cable lanyards, swaged fittings, and more. We strive to build long-lasting relationships with our customers, regardless of your industry. Contact us today and tell us how we...

Aero Assemblies, Incorporated strives to make every effort, as dedicated wire rope manufacturers, to maximize product value throughout the manufacturing process.

More Wire Rope Cable Manufacturers

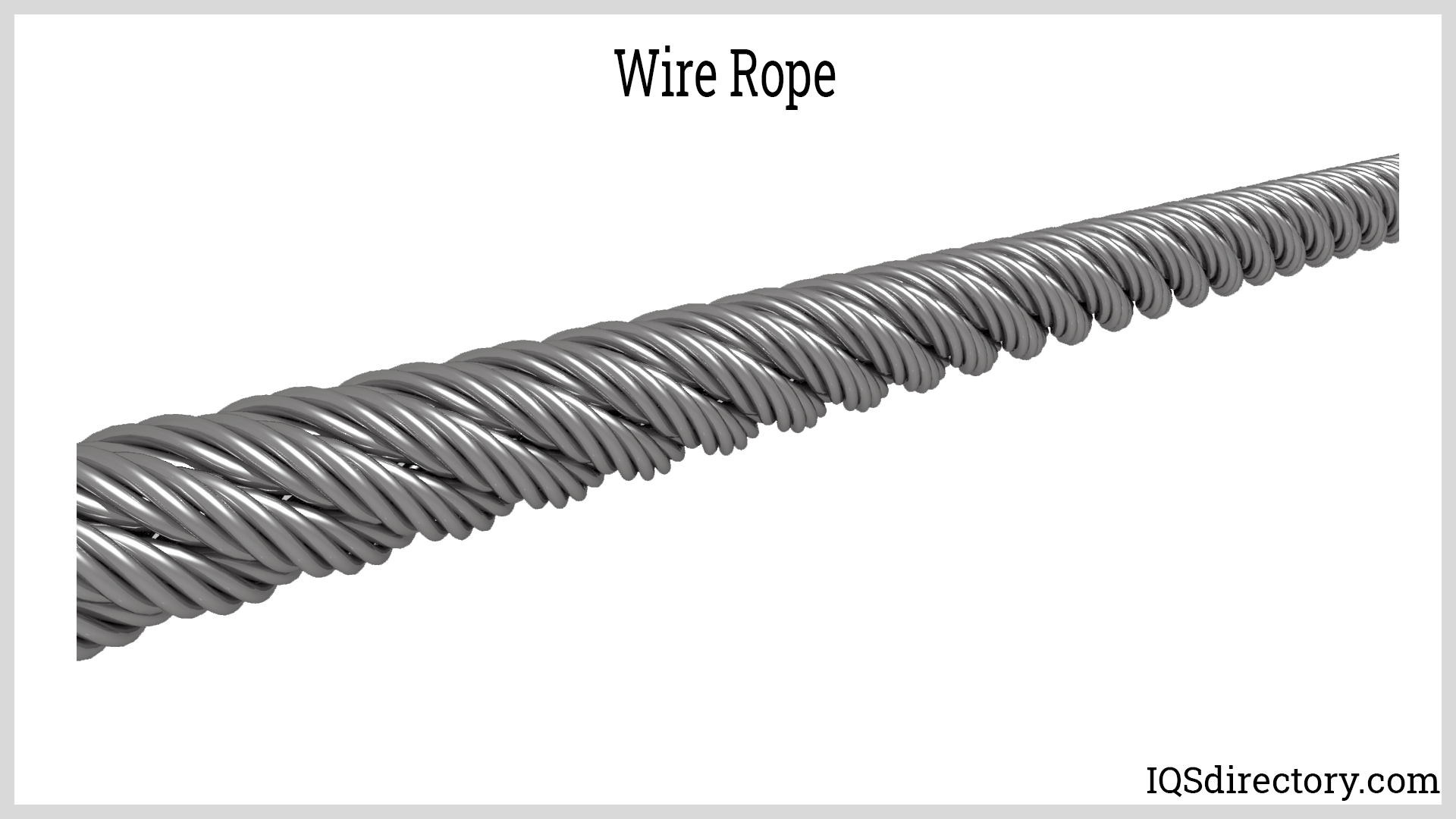

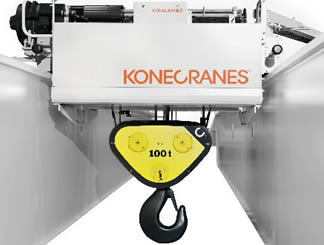

For various reasons, wire rope is a favored hoisting method. Its distinctive structure comprises several steel wires bent into separate strands and arranged around a core in a spiral arrangement. This structure offers resistance to bending loads, strength, and flexibility. For the particular lifting application, various material, wire, and strand configurations will offer various advantages, such as:

- Strength

- Flexibility

- Abrasion resistance

- Crushing resistance

- Fatigue resistance

- Corrosion resistance

- Rotation resistance

Considerations to be made when choosing the right wire rope for lifting applications require some thought.

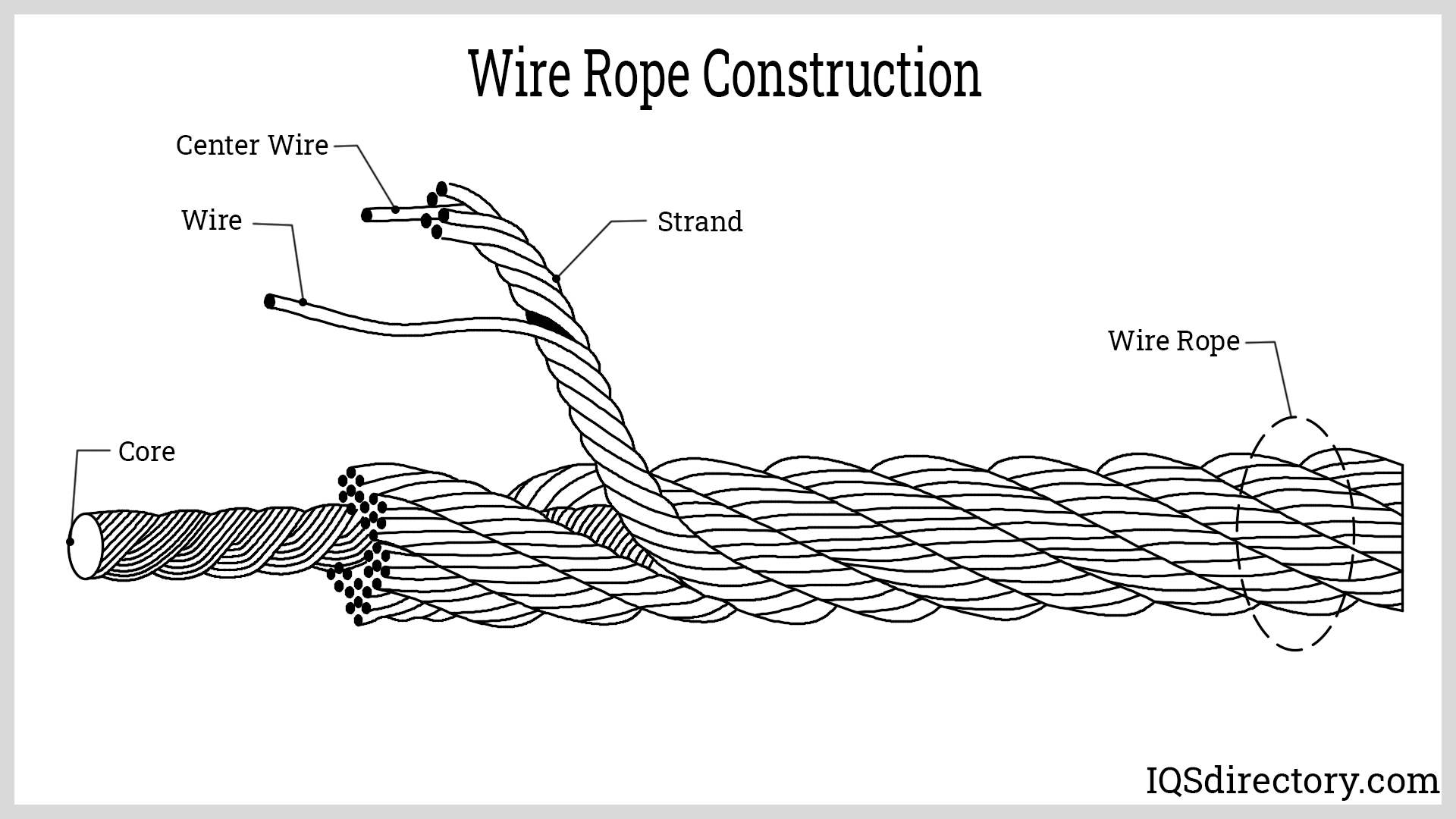

Wire Rope Construction

Four basic components make up the design of a finished wire rope:

- Metal wires that are one continuous strand.

- Helix-shaped multi wire strands arranged around a core

- a steel or fiber core

- Lubrication

Common Terms Relating to Wire Rope Cable

Wire

The smallest component of wire rope, wires make up each rope strand. Metals like steel, iron, stainless steel, metal, and bronze can all be used to make wires. The wires can be produced in several grades related to the wire rope's strength, wear resistance, fatigue resistance, corrosion resistance, and curve.

Although the wires can be coated, "bright" or uncoated finishes are most frequently offered.

Strands

Two or more wires are twisted in a certain pattern to create the wire rope strands. The individual strands are then arranged around the rope's core in a spiral pattern. While strands made of smaller-diameter wires are more flexible, strands made of larger-diameter wires are more abrasion-resistant.

Core

A wire rope's core, which runs through the middle of the rope and supports the strands, aids in keeping the strands in relative alignment under bending and loading stresses. Steel, natural or synthetic fibers, and other materials can all be used to create cores.

Lubrication

During the manufacturing process, lubrication is applied and permeates the entire structure. There are two main advantages to lubricating wire rope:

It provides corrosion protection and lubrication in the core and exterior surface, which reduces friction as the individual wires and strands move over one another.

The terms listed below assist in defining the composition and characteristics of wire rope:

- Length

- Finish of Wires

- Grade of Rope

- Size

- Preformed or Non-Preformed

- Direction and Type of Lay

Type of Core

Length: The total number of feet provided after being wound around the spool (cut to size).

Size

Size refers to the wire rope's stated nominal diameter, which can be given in millimeters or inches.

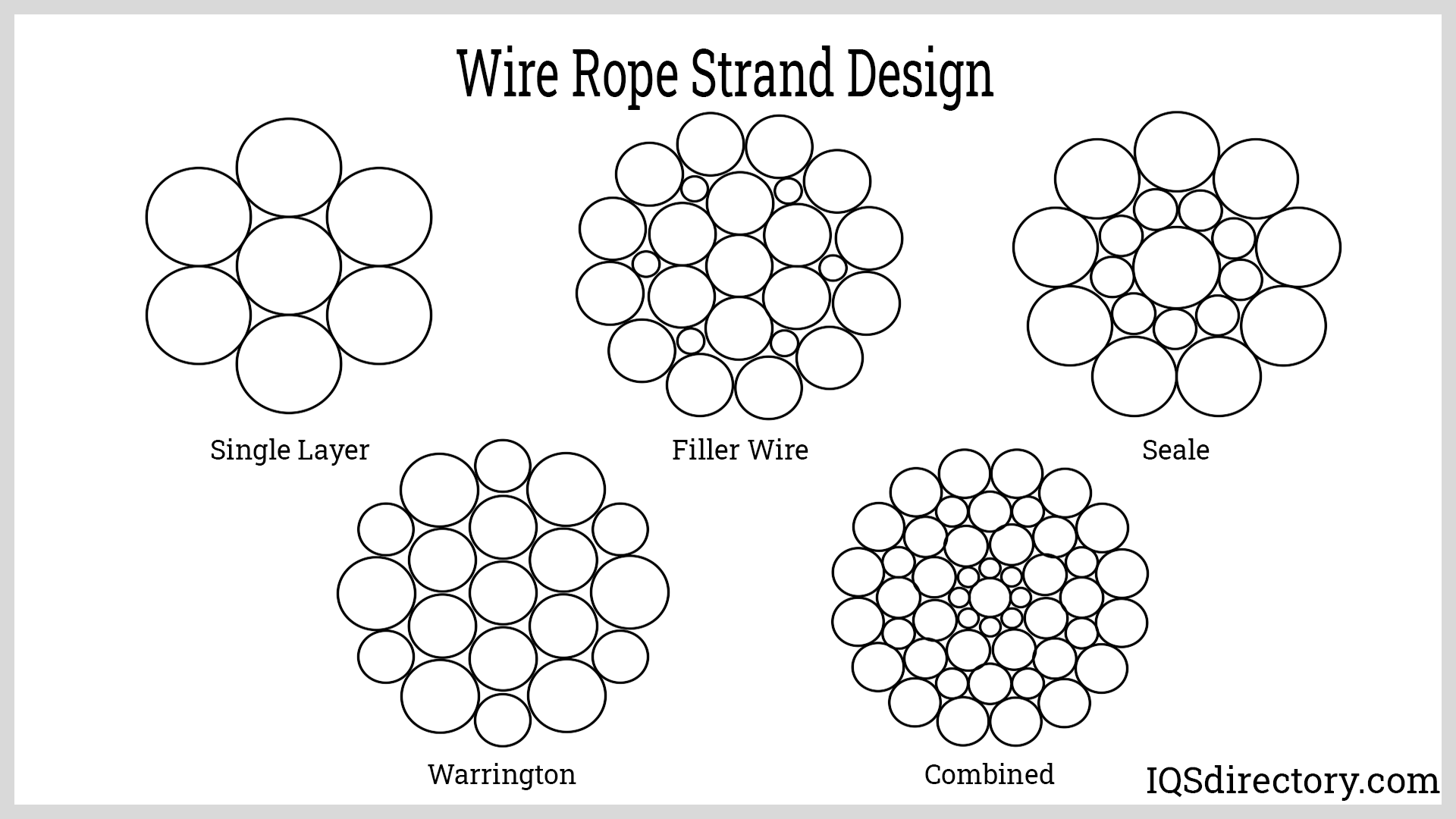

Strand Designs

Strand design is used to describe wire rope. The type of strand pattern is influenced by the number of wire layers, the number of wires on each layer, and the size of the wires per layer. Wire rope can be made using one, two, or more of the following patterns.

Single Layer

The most typical example is a seven-wire strand with a single wire in the middle and six wires surrounding it that are the same diameter.

Filler Wire – A center is surrounded by two layers of uniformly sized wire, with the inner layer having half as many wires as the outer layer. In valleys of the inner wire, a similar number of little filler wires are laid as in the inner layer.

Seale

The wires are identical in the two layers surrounding the center. Each layer's wires have the same diameter. The dips between the smaller inner wires are where the large outer wires rest.

Warrington

Two wires are organized around a central point with one diameter of the wire in the inner layer and two alternately large and tiny diameters of wire in the outer layer. The smaller inner layer wires sit on the inner layer's crowns, whereas the bigger outer layer wires rest in the valleys.

Combination

Any combination of two or more of the aforementioned patterns can create a combination strand.

Preformed

The strands and wires of a prepared wire rope are molded to the spiral shape they will take in a finished wire rope during manufacturing. Preformed rope has a few uses where it can be helpful, such as when it needs to spool more evenly on a drum, be more flexible, or have stronger fatigue resistance when bending.

Direction and Type of Lay

The direction and lay describe how the strands are put around the core and how the wires are laid to make a strand (either right or left) (regular lay, lang lay, or alternate lay).

- Regular Lay: The wires align with the rope's axis. The wire is laid in the strand in the opposite direction to how the strand is laid out.

- Lang Lay: The axis of the rope and the wires are at an angle. Around the core, the wire and strand are laid out in the same direction. As a result, the fatigue and abrasion resistance of Lang lay ropes are high. Lang lay ropes spool poorly in a drum and are less naturally rotation-resistant and more resistant to crushing forces than regular lay ropes.

- Alternate Lay: This wire rope, which is typically used for specialty applications, has alternating strands of Lang lay and regular lay.

Grade of Rope

The strength of most steel rope wires is determined using the plow steel strength curve. Various classes of wire rope's tensile strength exist, including:

- Improved Plow Steel (IPS)

- EIPS, or Extra Improved Plow Steel, is 15% stronger than IPS.

- Compared to EIPS, Extra Extra Improved Plow Steel (EEIPS) is 10% stronger.

Types of Wire Rope Cores

The types of wire rope cores are:

- Fiber Core (FC)

- Independent Wire Rope Core (IWRC)

- Wire Strand Core (WSC)

Polypropylene fibers can be found in both natural and synthetic fiber cores. Although fiber cores are more crushable and are not advised for high heat conditions, they are more elastic than steel cores.

An independent wire rope or strand can have a steel core. Steel cores are the best choice for applications where a fiber core might not provide enough support or in a working environment where temperatures might reach 180° F or above.

Choosing the Proper Wire Rope Cable Manufacturer

To make sure you have the most positive outcome when purchasing Wire Rope Cable from a Wire Rope Cable Supplier, it is important to compare at least 5 Manufacturers using our list of Wire Rope Cable suppliers. Each Wire Rope Cable Supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Wire Rope Cable business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Wire Rope Cable companies with the same form.

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services