A control cable is a wire rope. Developed in the 19th century, control cables include everything from the cables used in suspension bridges to the smaller strands that give the brims of women’s hats their shape. Since the beginning of aviation, control cable has been a mainstay due to its numerous useful functions, which include transmitting a control input around a corner and bracing a wooden wing. It is also lightweight, dependable, affordable, and versatile. Read More…

As leading innovative wire rope manufacturers, Bergen Cable Technology has been providing engineering assistance for well over half a century, helping customers develop cost effective, durable solutions.

JSC, as one of the most diversified wire rope manufacturers, utilizes over 200 production machines to produce top rated wire products in ferrous and nonferrous materials. Industries that JSC serves include electronics, geophysical and communications.

Lexco is an ISO:9001 manufacturer of wire rope, cable, and bungee cord assemblies; and push-pull controls. Our in-house capabilities range from swaging and extrusions to die-casting, proof-loading, and CNC machining. Lexco Cable is proud to serve a diverse set of markets including military, aerospace, OEM, MRO, marine, architectural, and more. Contact us today.

For over 30 years, companies across various markets have relied on Motion Control Technologies to provide high-quality mechanical cable solutions. Our line of products includes commercial cable lanyards, galvanized wire rope cable lanyards, swaged fittings, and more. We strive to build long-lasting relationships with our customers, regardless of your industry. Contact us today and tell us how we...

Aero Assemblies, Incorporated strives to make every effort, as dedicated wire rope manufacturers, to maximize product value throughout the manufacturing process.

More Control Cable Manufacturers

Control cables are mechanical motion transmission cables that transmit the operator's signal or action to the designated control point. Due to the characteristic of their use, control cables must be:

- Accurate in action

- Environmentally friendly (suited to sub-zero temperatures, corrosive conditions, dirt-dust accumulation, submersion in oil, etc.)

- Simple to mount and demount in a tight, complicated space

- Flexible during its operating lifetime and can be modified or recalibrated

Types of Control Cable Operation

To make customized cables suitable to individual applications, control cables must be manufactured from a wide variety of materials and components. As a result, control cables are divided into two categories based on how they operate mechanically: PUSH-PULL and PULL-PULL cable.

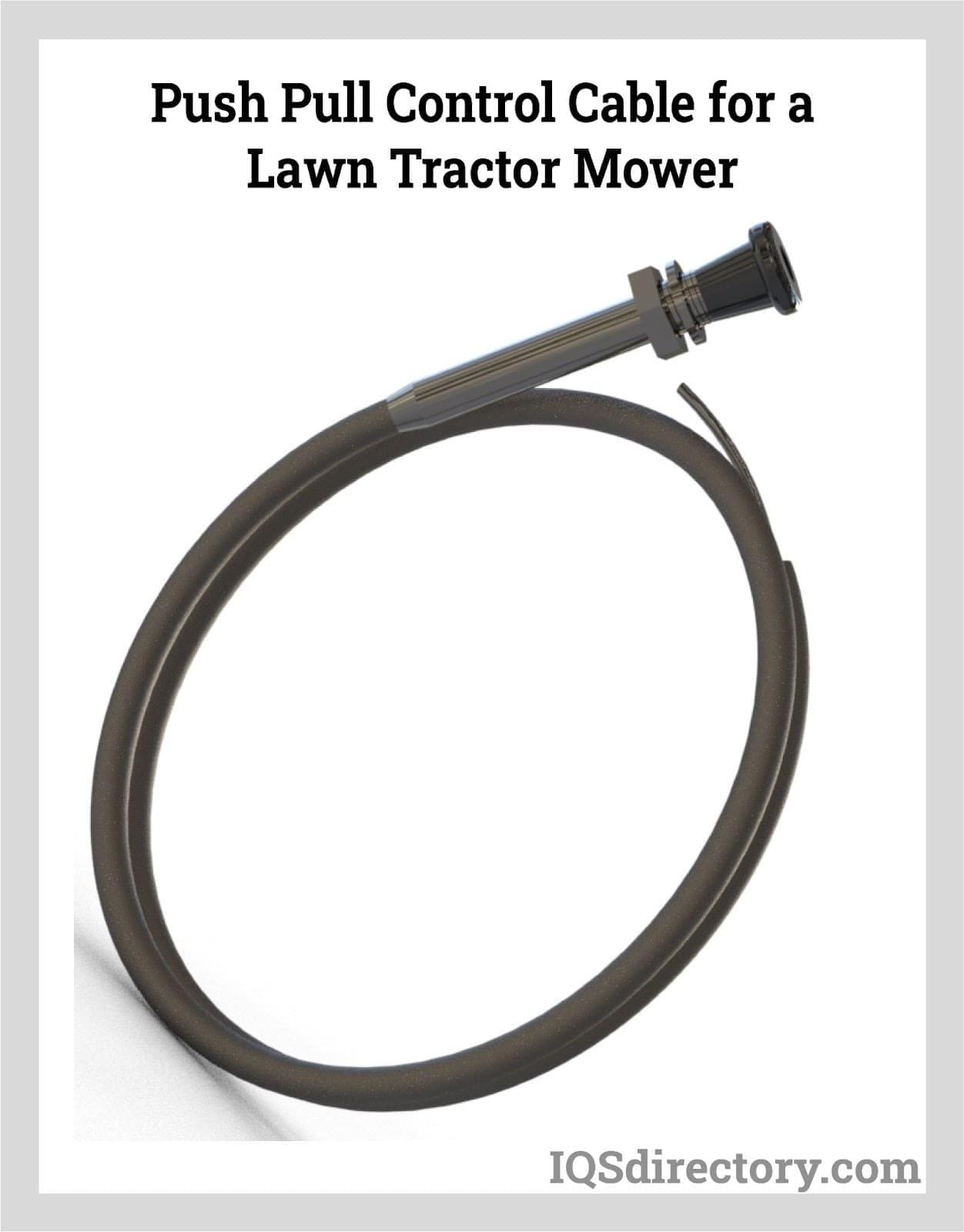

Push-Pull Control Cables

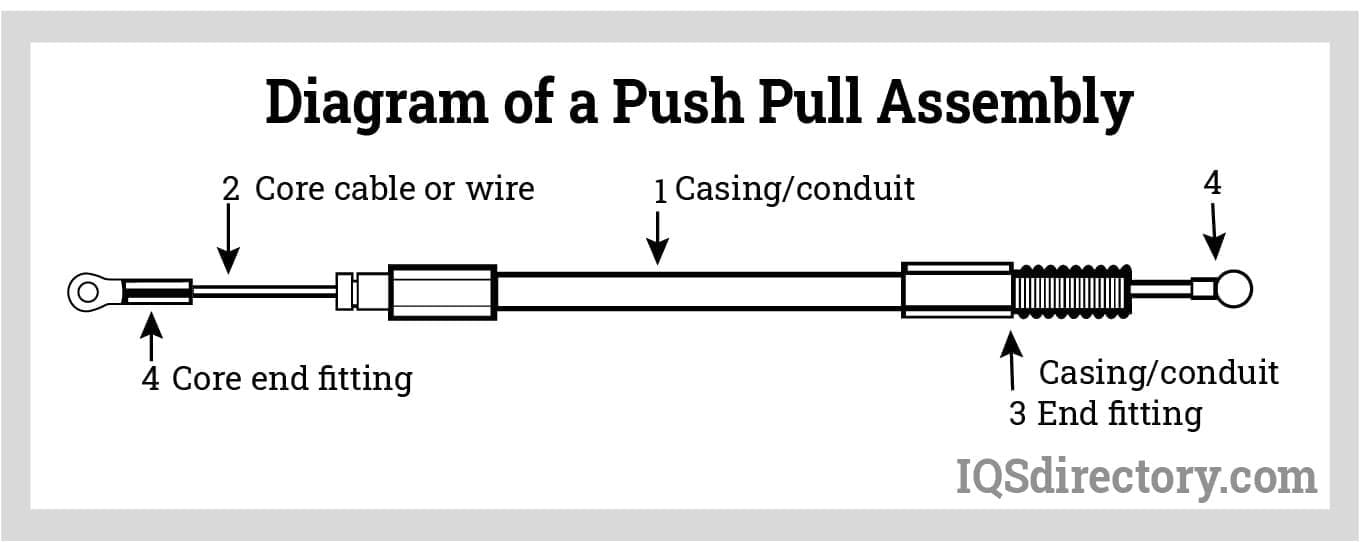

A push-pull control cable transmits motion by compressing or pushing in one direction and pulling or tensioning in the opposite direction. Applications requiring the transmission of forces in both the push and pull modes of operation employ push-pull control cables. To avoid using additional fittings or terminations, solid wire cores can be produced on the ends. The end fittings (pictured) can be used in any arrangement. To prevent a permanent set in the core wire, bend radii should be wide and routing should be straightforward.

Pull-Pull Control Cables

In a pull-pull control cable, the operator applies tension or pulling force in one direction. Pull force is successively used to transfer motion in the opposite direction. The control cable returns to its neutral or initial position by spring actuation.

Control Cables Manufacturing Process

It's crucial to look at the control cables' sub-assemblies to comprehend their production and user selection. The following parts can be found in a control cable:

- Conduit

- Core

- End Fittings

Conduit

The conduit is the sleeve that gives the control cable cores a dedicated course of travel, making it easier to route control cables in complex non-linear applications. Conduits are essential to the successful design of the control cables and have a variety of uses, including:

- Increasing the service life of control cables

- Maintaining precise motion transmission

- Dedicated padded travel route

- Defending against the entry of outside pollutants

- Deterring corrosion and abrasion

The following subassemblies make up conduits: a liner (through which the core cable travels), a wrap (which gives the cable assembly flexibility and protection), and a jacket (which act as a sealing layer against the external environment).

The application environment primarily determines which of the following three types of conduits should be used for these cables.

- Braided Conduit

- Bowden Conduit

- Long Lay Conduit

Bulkhead Fittings / Core Fittings

Bulkhead fittings, core fittings, end fittings, and intermittent transmission fittings are chosen based on the reapplication (push-pull, pull-pull), the length of the cable, and the path the control cable is routed through. These fittings can be designed for the application based on the user's specifications.

Core Cable

The cable that transmits motion and moves through the conduit is called the core cable. The can be either stranded or solid depending on the operating type (push-pull or pull-pull).

Push-Pull: Solid cores are preferred for control cable cores.

Pull-Pull: Stranded cores are preferred for control cable cores.

Control Cable Applications

Various industries use control cables because they are simple to install, repair, and maintain. Control cables have several recognized applications, including:

- ATVs

- Utility Vehicles

- Wheelchairs

- Construction Vehicles and Equipment

- Outdoor Power Equipment

- Medical Equipment

- HVAC Controls

- Fixed Wing Aircraft Systems

- Industrial Systems

- Helicopter Systems

Control Cable Maintenance

- The fine wires of the cable's interstices must be free of dust and dirt accumulation. As the dirt flexes, the wires wear down and eventually fray.

- Never use a solvent to clean a cable, which removes the lubricant that supports the cable's elasticity. Instead, a fresh rag should be used to wipe it down.

- In aviation, visually check for fraying or broken strands by passing a gloved hand along the cable during pre-flight inspections and routine maintenance. A few damaged wires are not immediately alarming, but they indicate that the cable is under stress and must be regularly inspected for different symptoms of deterioration.

Choosing the Proper Control Cables Company

To make sure you have the most productive outcome when purchasing Control Cables from a Control Cables Supplier, it is important to compare at least 4 or 5 Companies using our list of Control Cables suppliers. Each Control Cables Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Control Cables business website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple Control Cables businesses with the same form.

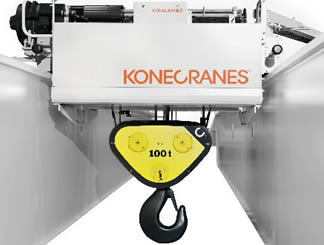

Cranes

Cranes Electric Hoists

Electric Hoists Forklifts

Forklifts Hydraulic Lifts

Hydraulic Lifts Rope

Rope Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services